Tsuki gets a brand new engine!

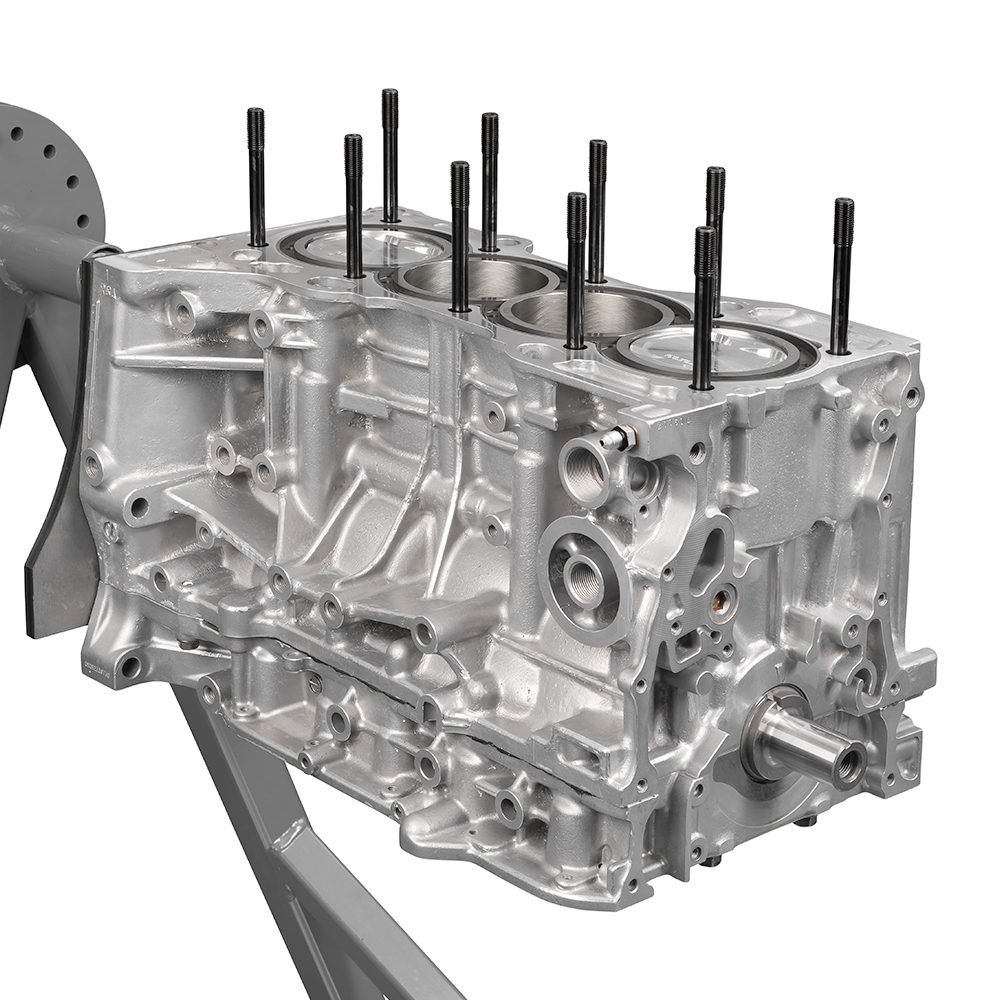

We’re always on a mission developing Tsuki, our Honda NSX, to make it as fast as possible. In our latest development, we’ve got a brand new engine from Bourne HPP! Their K22 now features some very special parts, so let’s take a look at what they are.

The Bourne K22 uses a bowled piston crown design, typical of the type found in modern turbocharged endurance and rally engines. These are manufactured by Pankl pistons, featuring the thickest crown known on a K-series engine. The added material in the piston crown design enables us to run higher cylinder pressures increasing engine output and overall on track performance. The piston has been designed using Pankl’s stress analysis software leaving no stone unturned in added strength whilst reducing overall weight. The pistons also feature beryllium bearings and a DCL coated gudgeon pin for increased durability.

Terry Radbourne, owner of Bourne HPP, sums the piston assembly up, saying, “It’s pretty much a Formula 1 piston in an engine based on a Honda K20.”

Bourne HPP have also developed a couple of parts for the engine too with their billet high lift cams and valve train. They are manufactured right here in Britain, in a traditional heat-resisting austenitic steel that has found to be durable in high performance motorsport. The valve sizes for both the inlet and exhaust are increased by 1mm and are available to purchase on our website. These are capable of seeing over 300 horsepower on an N/A build and up to 1,000 on anything boosted!

A set of Mahle Motorsport bearings now feature too, these are actually made by the same people who make bearings for F1 engines.

The original K20 cylinder block was originally fitted with dry liners – that is, steel sleeves inserted into bores in the block casting. The Bourne K22 is fitted with wet steel liners from US supplier Darton, to Bourne’s specification. This involves a great deal of machining and material removed from the Honda block.

The crankshaft has been made by Arrow Precision, who also make the con rods too. This is a flat-plane, five-bearing, four-pin crankshaft made from 722M24 nitriding steel. The material is hardened and tempered to give a core strength in excess of 1000 MPa. At 12kg, the crankshaft is far lighter than the OEM Honda crank, which is achieved mainly by reducing the number of counterweights from 8 to 4. The crank and rod design brief was to run to 9,500rpm reliably whilst lowering vibration and thus wasted energy within the engine.

The Garrett G30-770 (0.83 AR) remains in the boot of the NSX once again and has been faultless so far throughout the build. We have cranked the power up to 650 horsepower which is well within the turbos maximum capacity of 770 horsepower and we still have room to push even further!