The Ultimate K-Series Drop-in Cam Test

THE ULTIMATE K-SERIES DROP-IN CAM TEST

Almost a year later than planned, we’ve finally carried out the eagerly anticipated drop-in cam test for the Honda K20 engine. This test hopes to further build upon previous testing we’ve done (intake manifold and induction kit) and hopefully help readers to decide on future build plans for their K-series engine. To ensure a fair and even test, we were joined by Jesse Halford from J.Cal ECU Calibration and Paul West from TPW Engineering.

Jesse is renowned in the Honda tuning scene and was the wizard who set about mapping the car and ensuring each dyno run was conducted as fairly as possible. With over 35 years’ experience, Paul might be better known from his days at TDi North where he is their resident tuner and developed the TDi Ultimate cams that we’d be testing. With a much better understanding of how the cams work and performed, it’s time to hand you over to Jesse, who explains the findings in a better way than I ever could!

Before we start, I’d like to point out a couple of things and with much of this subject being covered on the Tegiwa YouTube Channel, but:

- I’m shockingly bad in front of camera.

- I know a lot of readers like to well, read!

With that being said, onto our test car. We have a basic K20A2 slapped into an EK Honda Civic, quite literally, due to Mike finishing the engine swap at 1am the night before the tests! Basic bolt-on parts include the Skunk2 Ultra Street Intake Manifold and Skunk2 Velocity stack intake that you may have seen in other test articles. The fairly new to the market Tegiwa K-swap exhaust manifold, which features a fairly large runner, 4-1 style exhaust manifold with a megaphone 3” exit and into a 3” Greddy cat-back. Finally, Grams 550cc injectors just to be sure that we don’t run out of fuel. So, as you can see it’s a pretty basic spec engine that a set of camshafts would be the next logical step for.

Anyway, without further ado, lets meet our contestants; Stock K20A2 (EP3), JDM K20A (DC5), Drag Cartel 8620 Billet OG DIC, TDi North Ultimate and Skunk2 Tuner Series DIC.

All of these camshafts are designed and rated for the stock valve train in a Type R K-series engine, so they’ll have been designed within the same limiting factor. Granted, some may favour a different spec of intake/exhaust manifold but unfortunately, we can’t test every combo. We’ve got what we’ve got.

The camshaft swaps themselves were covered by the guys at Motion Motorsport. Each time it was left to cool down as close to ambient as was reasonably possible before setting the valve clearances to the specs supplied by each manufacturer. Consistent air and coolant temps were held throughout the testing with minor changes to ambient conditions throughout the course of the test.

Results

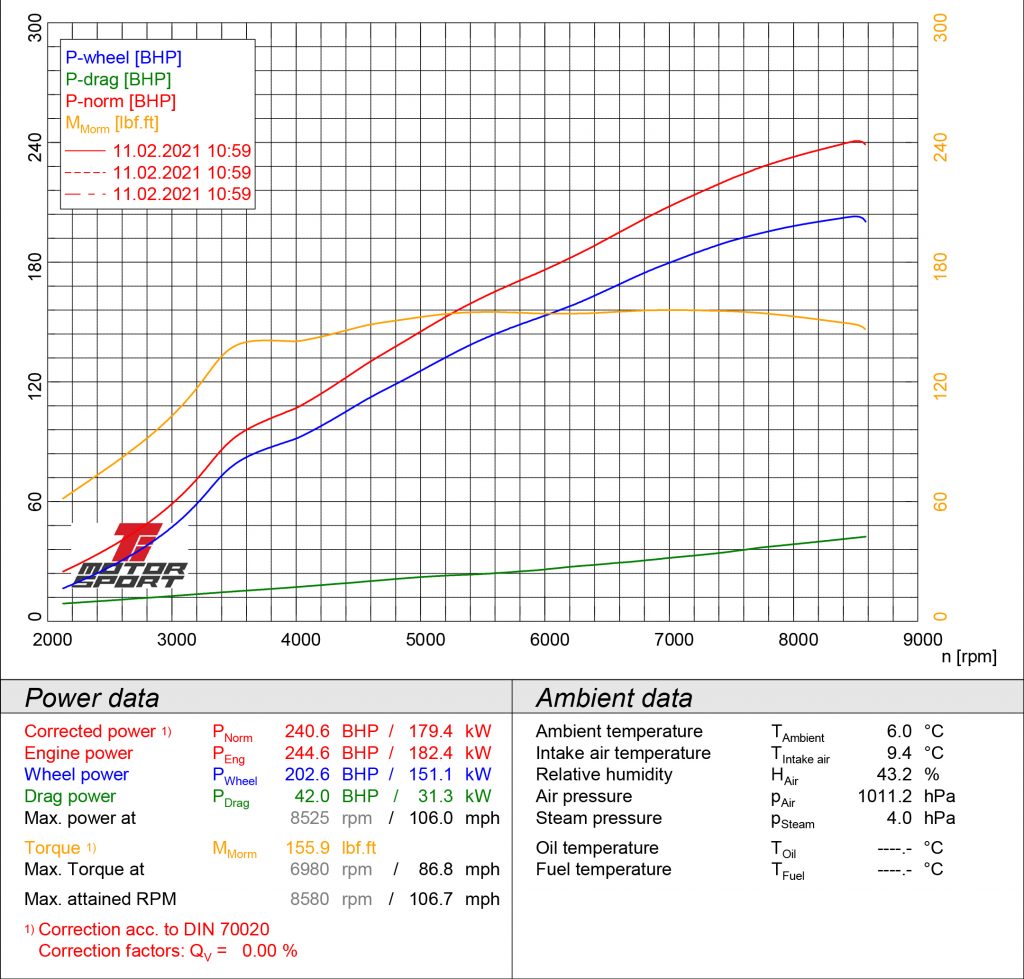

Stock K20A2

We ran with the stock camshafts in first. This gave us baseline HP and torque curves so we can then compare the rest against them as we work our way through the different options. So, in pretty predictable fashion the car ran in at 240hp and 155lbft of torque. Peak torque for the low cam was 140lbft. Generally speaking, this is the lower end of what you’d expect to see a K20A2 of this spec to make, but results can vary widely on many factors, which is why we do these tests on the same engine and dyno. It did look as though we may have found more power with a little more RPM, but we wanted to keep the 8600-rev limit that we would impose on engines with DIC’s and stock valve trains. I wasn’t keen on customers coming in and expecting to see their stock oil pump and stock valve train K20s at a true 9000rpm.

240.6 hp / 155.9 lbft

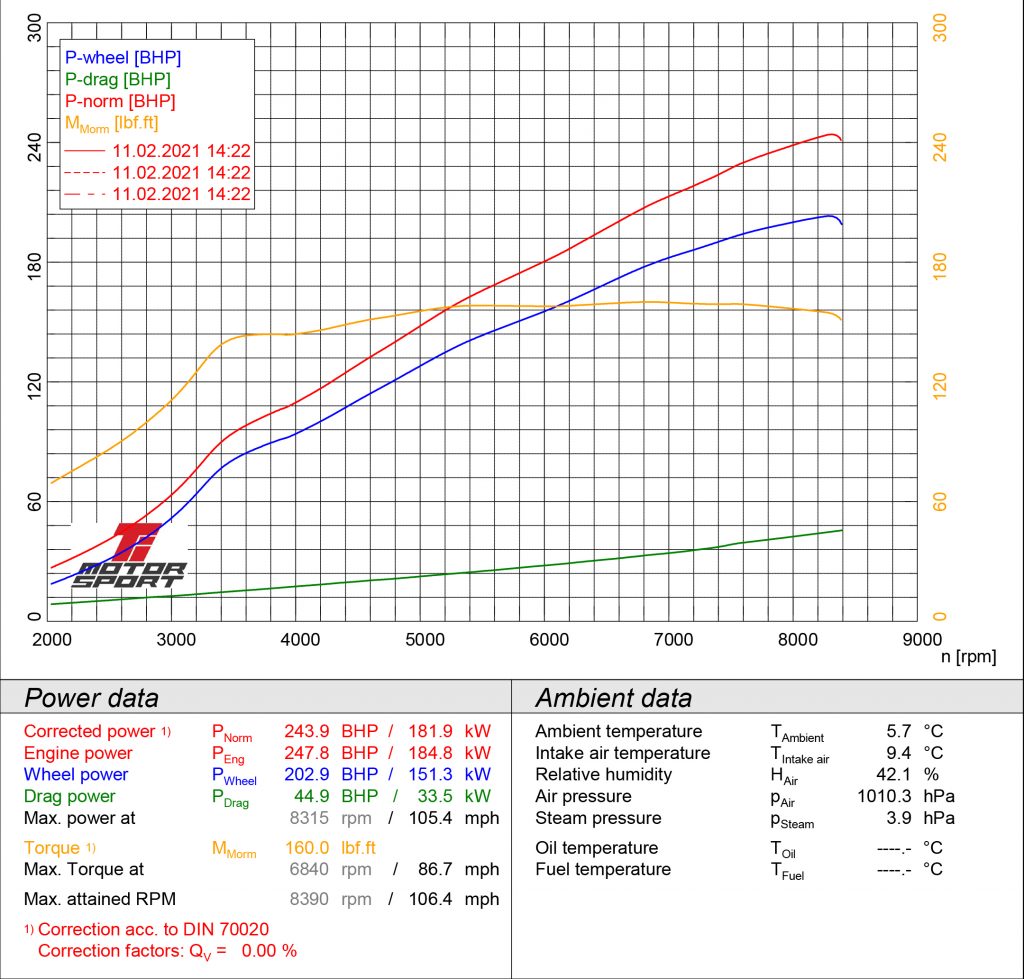

JDM K20A – £619.99

We decided to test these mainly out of interest more than anything else, although some people do use the JDM cams as an upgrade. We weren’t too sure that the gains would be all that measurable, however, there’s only one way to find out!

Now, I will hold my hands up here and say I made I minor balls up of the dynos RPM scaling on this cam test. It’s very difficult to match the scaling dead on every time and this time, I was off by about 200rpm or so at redline. This was due to tuning customer cars in between the cam testing and I had to rescale the RPM on the dyno. This explains the reason why it looks as though we’ve not revved the JDMs out as far as the rest of them, but we did. It may also be responsible for a very minor bump in the torque curve but nothing major. Fortunately, I got the scaling correct for the 3rd cam and then no other customer cars in between, so from here on out, scaling is literally identical.

So now that the critics have their answer, its back to the results; the K20A cams came in with a nice 3hp increase and a torque gain everywhere (remember the scaling). This surprised me, as no more than a week or two before, I had a customer’s car in for tweaks, and the results were basically identical to his K20A2 cams previously. VTEC came in at the same 4000rpm and the curves look very similar, just with the JDM’s making that bit more everywhere. Would I go to the trouble of fitting a set? Probably not to be honest. If I had them lying around and I happened to be doing a cam chain or something, then I might do.

243.9 hp / 160 lbft

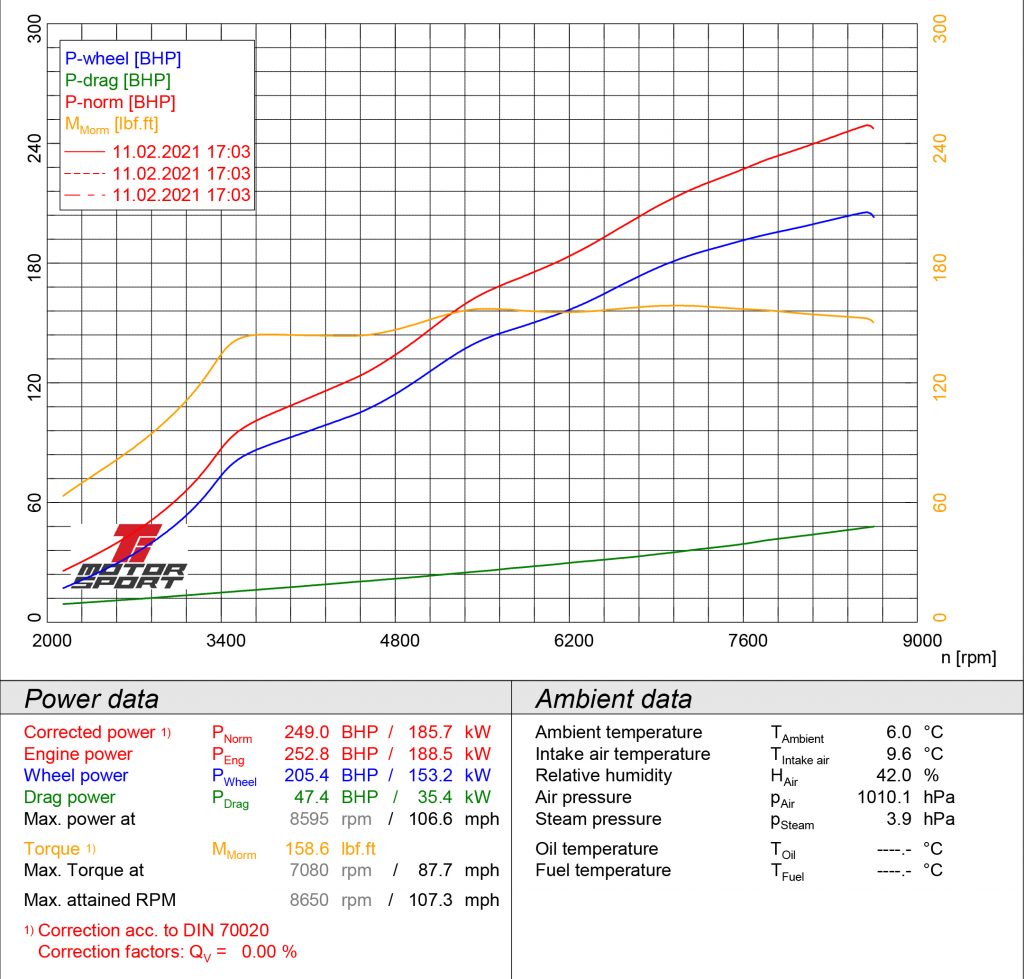

Drag Cartel DIC – £1,052.18

Onto our first aftermarket camshaft, DC-DIC. There’s no way that we’re doing any camshaft testing on any K-series without a Drag Cartel product featuring, so their DIC were a must have!

Anyway, straight onto the results. We found modest low cam gains on the stock cams; 144lbft, so a 4lbft increase there over the whole low cam operating range. VTEC came in marginally later at 4500rpm but an instant response was seen from the engine as it jumps to high cam and brings torque and power gains with it. These were the strongest camshafts of the whole test in that 4800-5800 bracket and have made the high cam work well in that rev range, even on this pretty peaky setup. It seems the setup really wants the rpm as we are still climbing at the 8600 redline but engine longevity is critical.

249 hp @ 8600 158.6 lbft @7000

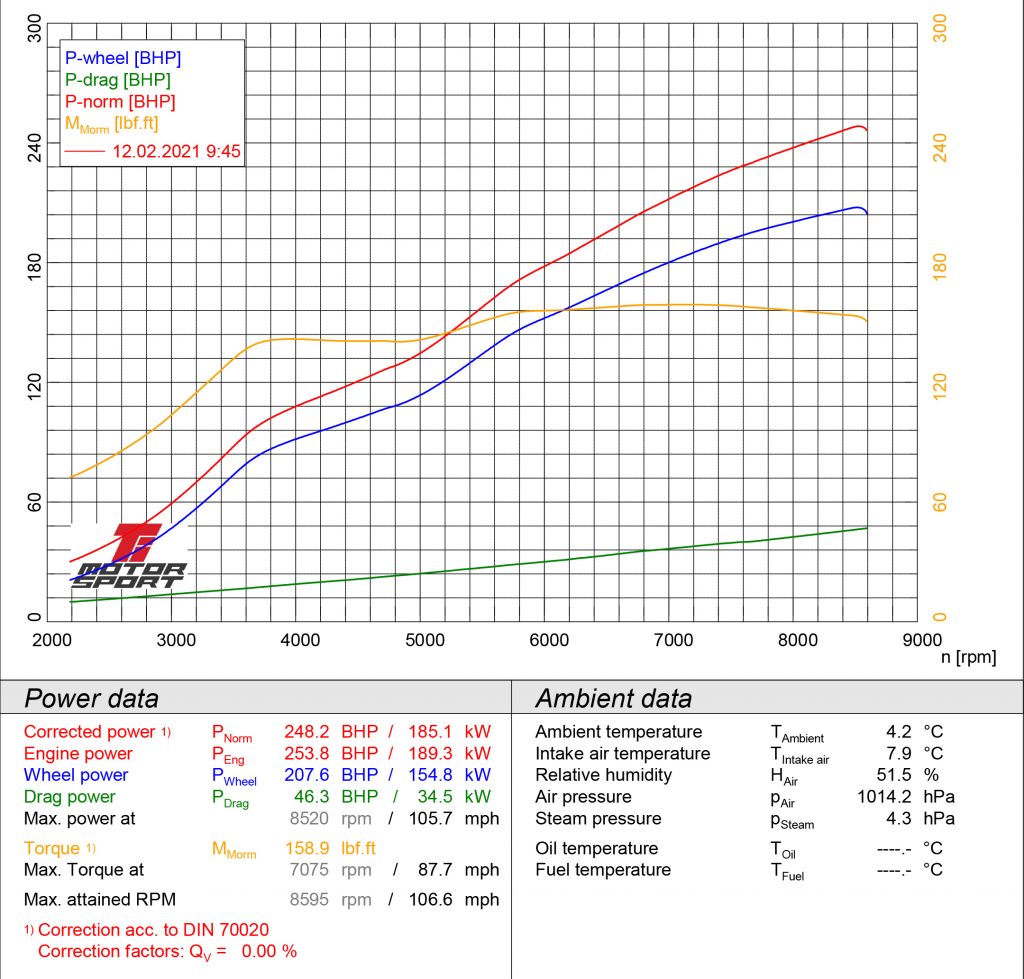

TDi North Ultimate – £1,200

So, these were the hardest cams to source and were certainly the joker in the pack for us. We weren’t quite sure what to expect from them, having not tuned too many, but they certainly didn’t disappoint!

Low cam results weren’t as strong as the Drag Cartels with 142lbft for the majority of the low cam operating range. VTEC was in marginally later at 4800, and the real grunt from the high cam didn’t come through until around 5500rpm. However, once there, they outran everything in the 5800-7500rpm bracket. It seems they can’t use the high cam at lower RPM as effectively as the DC’s can, but are stronger over the upper midrange region, levelling back off to essentially identical when it came to redline.

248.2 hp @8600 158.9 lbft @7000

Skunk2 Racing Tuner Series DIC – £732.61

A very popular camshaft here in the UK is the Skunk2 DIC; another one that we couldn’t miss out, especially given Skunk2’s results in previous tests.

We found VERY strong low cam performance from these with 150lbft (you weren’t expecting that were you!?) Now, in my opinion this is probably the best thing about the Skunk2’s, but from customer feedback over the years, it appears this is one of their downfalls as well. Due to the low cam being so strong and the high cam so aggressive it tends to push the VTEC crossover to a higher RPM (5500 here). However, you’ll notice that they make nearly the same torque on the low cam as they do the high cam. This appears to give the driver an exaggerated sense of lacking midrange, when in fact, they simply have such a strong low cam performance that they aren’t feeling the increase as VTEC comes in, they already have it from the low cam. Essentially some people struggle with the concept that early VTEC does not equate to power and they need the crossover as soon as possible.

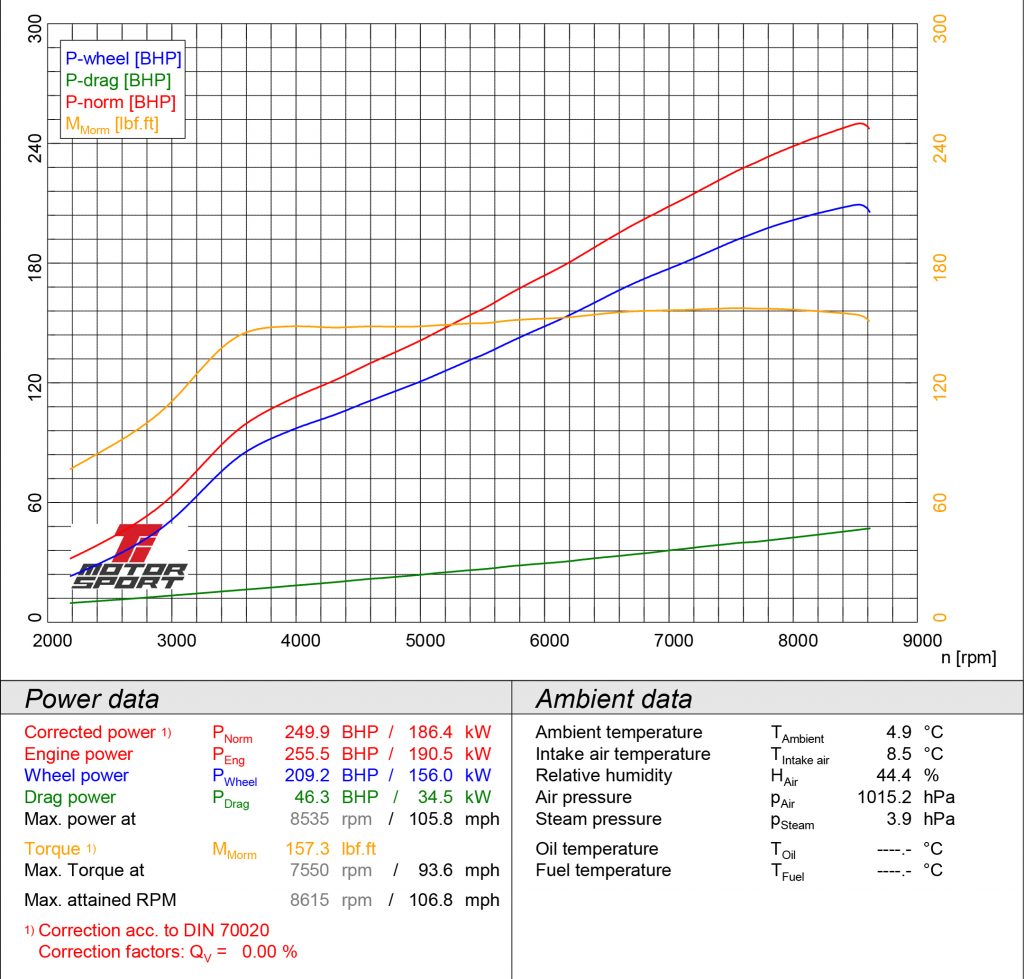

So, as we can see, the Skunk2’s are by far and away the best for low cam performance which I’m sure will surprise many. They aren’t the strongest of our contestants in the midrange, losing out roughly 6lbft at 5500RPM to the strongest cam at that point (the DC). The high cam then overtakes the rest around the 7800rpm mark to go on to 249.9hp. I’d imagine more RPM would see the gains over the others widen, but the test car isn’t safe for much over 8600rpm.

249.9 hp @8600 157.3 lbft @7500

Summary

So, that’s our testing complete, what can we conclude from this?

We saw 8-10hp peak gains over stock with surprisingly good low cam gains to be had. In VTEC, torque tends to be shifted with desired rpm range more than a total torque increase.

It’s a nobody but everybody wins situation here as there’s little in terms of peak power difference between the 3 aftermarket brands we tested, 2hp between the 3 of them. Granted we may have seen another hp or two difference between them if we’d have revved them all out further. We have seen that each camshaft tends to favour a different part of the rev range though, and perhaps this will be the deciding factor for drivers.

The Skunk2’s are certainly the king of the low cam with some very good results over the others, but it’s once you hit VTEC that we then start to see RPM specific trade-offs going on. The DC’s making good work of that initial crossover, giving the early VTEC guys what they want and working well in the lower midrange. TDi North’s clear upper-midrange advantage should make for a fast setup for anything using that 5800-7500 bracket most often. Skunk2’s coming back with the high-end power to take the peak figures past 7800rpm.

Here’s a rough breakdown of the results for the 3 drop-ins tested at different RPM points.

Low cam results

- Skunk2

- Drag Cartel

- TDi North

5000 RPM

- Drag Cartel

- Skunk2 (still on low cam)

- TDi North

6000 RPM

- Bourne HPP (See 2022 update below)

- TDi North

- Drag Cartel

- Skunk2

7000 RPM

- TDi North

- Drag Cartel

- Bourne HPP (See 2022 update below)

- Skunk2

8000 RPM

- Skunk2

- Bourne HPP (See 2022 update below)

- TDi North

- Drag Cartel

So, there we have it then, our definitive results of the K20 drop-in cam test. Of course, it goes without saying that these results are unique to our dyno and test car. Different modifications and setups are going to bring different results, so don’t expect to see the exact same results if you’re thinking of putting DIC’s into your engine.

The final point to mention about this test is, fitting. Often a misconception when fitting drop-in cams is that it’s a huge job, but that is absolutely not the case. During the test we recorded Jim from Motion Motorsport’s time of changing the cams. His average time was 45 minutes, which involved removing the rocker cover, taking out the old cams, installing the new ones and re-fitting the rocker cover. Of course, he then has to alter and check valve clearances to make sure they run as intended, but again this should only take around 30 minutes for a mechanic that knows what they’re doing.

If you’re competent at working on your car then it’s a fairly straight forward job and something that most workshops should be able to do. As a rule of thumb, we would say that you should be looking at paying for two hours labour at the absolute maximum (providing it’s a simple swap and they don’t run into any problems). If a garage is trying to charge a full day’s labour, then something is seriously wrong!

Again, a big shout out to Jesse for carrying out the test, Paul from TPW Engineering for taking the trip over to us, Motion Motorsport for swapping each set of cams over and Mike for his hard work and late nights getting the car ready in time for us!

Make sure you check out our YouTube video on this test too, as you can see exactly how the day’s testing went. You’ll also be able to watch the build video on Mike’s car too as he prepares for the 2021 Time Attack Season. Stay tuned to the blog for results on our ECU test in the near future too!

*2022 Update*

Bourne HPP Street Drop-in Cams – £1,170.00

Since the release of this blog back in February 2021, there’s been a new drop-in cam to the market from Bourne HPP. Developed and engineered right here in the UK, the results are nothing short of impressive.

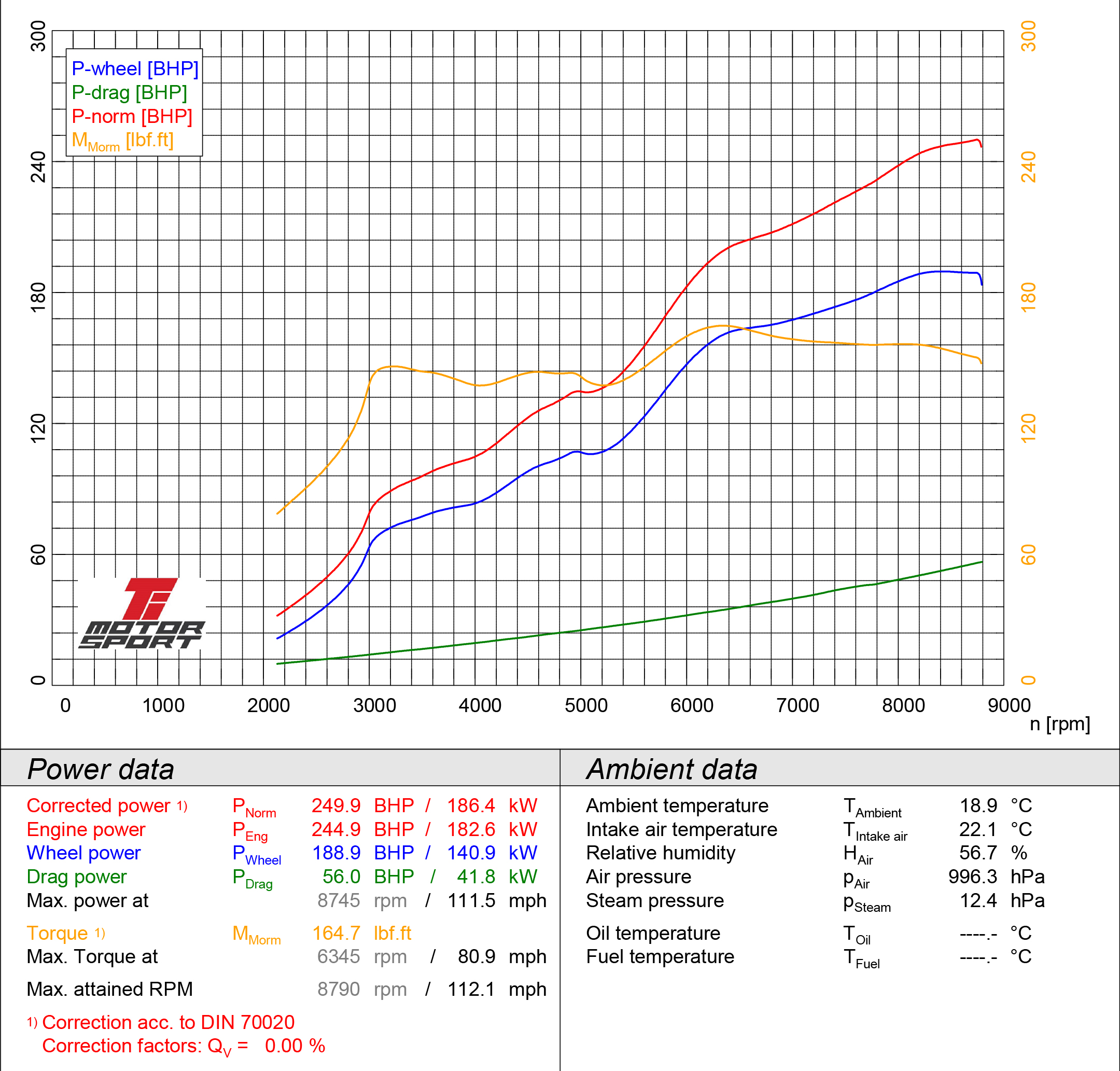

Although we can’t replicate the test on the car we’ve tested the others on, we have however, tested them on a K20A2 powered EP3. The EP3 had basic bolt-on modifications including a Tegiwa carbon airbox, Tegiwa exhaust manifold and RRC intake manifold.

Considering this car only has a RRC manifold, not a Skunk2 Ultra Street Intake Manifold like the EK that we did the tests on, we saw peak figures of 249.9bhp and 164.7 lbf. ft, the same horsepower as the Skunk2 drop-ins and 4.6 lbf. ft more than the JDM K20A cams! We can speculate that the car could potentially make an extra 5 horsepower too when we look at our intake manifold test and compare the difference between the Skunk2 Ultra Street and the RRC. Plus, with a better map on this EP3, the torque figure would be a lot smoother than the results we have gathered here.